Chaizvoizvo izvi zvikonzero zvinotevera:

1. Kugadzirisa:

(1) Kuwedzeredza kugadzirisa kudzvanywa, kumhanya kwakanyanya, kuzara kwakawanda, nguva yakarebesa jekiseni uye kubata kumanikidza kunotungamira kune yakawandisa kushushikana kwemukati uye kuputika.

(2) Rongedza kumhanya kwekuvhura kwe mold uye kudzvanywa kudzivirira zvikamu kubva nekukurumidza uye nechisimba kudhonzwa kubva muforoma nekutsemuka.

(3) Kunyatso wedzera kutonhora kwemuumbi kuitira kuti zvikamu zvigone kubviswa nyore kubva muhutu, uye kuderedza zvakakodzera kutonhora kwezvinhu kudzivirira kuora.

(4) Dzivirira kutsemuka nekuda kweweld mamaki uye kuparara kwepurasitiki, zvichikonzera kuderedzwa kwesimba remagetsi.

(5) Shandisa yakakodzera mumiririri uye ita shuwa kubvisa aerosols nezvimwe zvinhu zvinonamatira kune mold pamusoro nguva zhinji.

(6) Residual stress of the workpiece inogona kubviswa ne annealing kupisa kurapwa pakarepo mushure mekugadzira kuderedza kuumbwa kwekutsemuka.

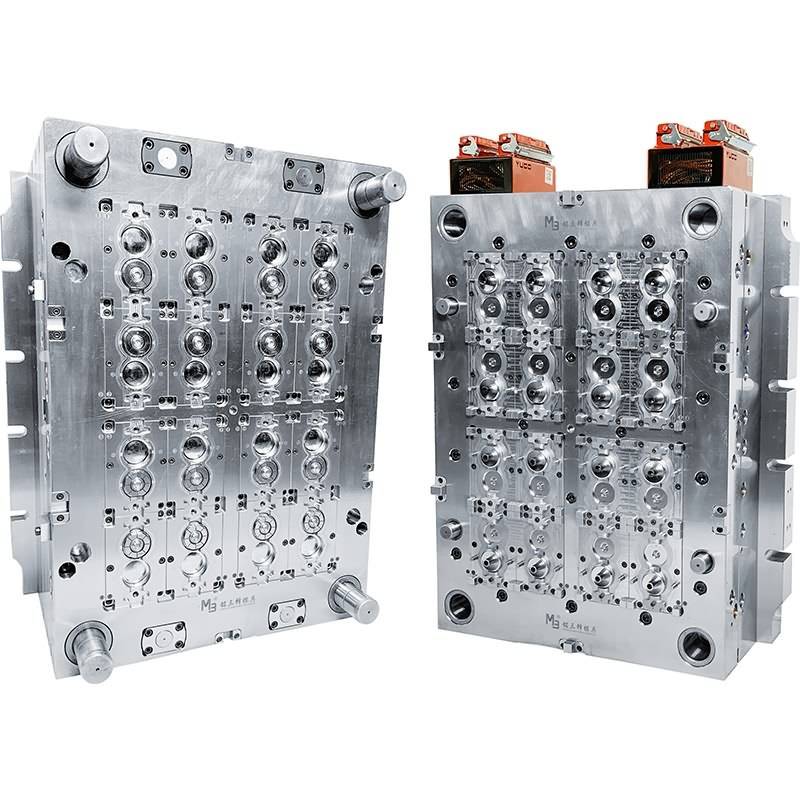

2. Mold chimiro:

(1) Iyo ejection inofanira kunge yakaenzana, yakadai senhamba uye chikamu-chikamu chechikamu chepini ejector inofanira kunge yakakwana, kutaridzika kwejector kunofanira kukwana, uye pamusoro pegomba inofanira kuva yakatsetseka zvakakwana kudzivirira kuputika nekuda kwe iyo concentration ye ejection residual stress nekuda kwesimba rekunze.

(2) Iyo workpiece chimiro hachifanirwe kunge chakanyanya kutetepa, uye chikamu chekushandura chinofanira kunge chine denderedzwa arc shanduko zvakanyanya sezvinobvira kudzivirira kushushikana kunokonzerwa nemakona akapinza uye chamfers.

(3) Kuderedza kushandiswa kwesimbi inopinza kudzivirira kuwedzera kwekushungurudzika kwemukati nekuda kwekusiyana kweshrinkage pakati pekuisa uye workpiece.

(4) Kune zvikamu zvakadzika-pasi, mapindiro emhepo akakodzera anofanirwa kupihwa kudzivirira kuumbwa kwevacuum negative pressure.

(5) Mugero mukuru wakakwana kuti zvinhu zvegedhi zviputswe kana zvikasaoma mune ramangwana kuti zvigone kuparadzwa nyore nyore.

(6) Kubatana pakati pe sprue bushing uye muromo kunofanirwa kudzivirira inotonhora yakaoma zvinhu kubva pakudhonzerwa mukati uye chikamu chinonamira kune yakagadziriswa mold.

3. Zvishandiso:

(1) Zviri mukati mezvinhu zvakadzokororwa zvakawandisa, zvichikonzera kuderera kwezvikamu zvesimba.

(2) Humidity yakanyanyisa, zvichiita kuti mamwe mapurasitiki aite makemikari nemhute yemvura, kuderedza simba uye kukonzera ejection kuparuka.

(3) Chinhu chacho pachacho hachina kukodzera kuti chigadziriswe, kana kuti kunaka kwacho kwakashata, uye kana chikasvibiswa, chinotsemuka.

4. Chimiro chemuchina:

Kuita kwemuchina weplasticizing kunofanirwa kuve kwakakodzera.Kana iri diki zvakanyanya, kugona kweplasticizing hakuzonyatso kusanganiswa uye kuve brittle.Kana yakakurisa, inotowedzera.

Nguva yekutumira: Sep-11-2023